case study #1

continental

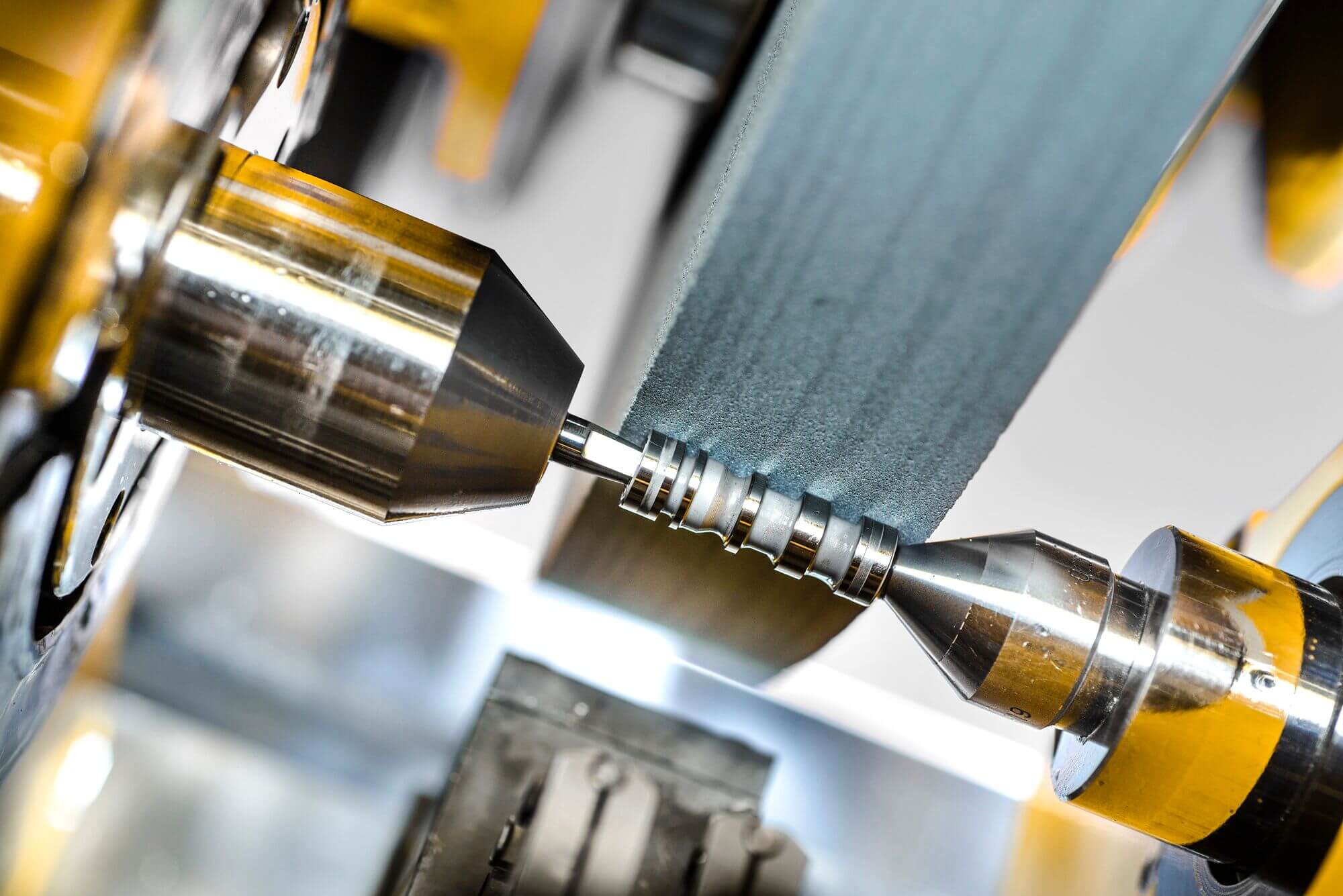

PROBLEM: Continental Automotive’s Newport News plant was managing a low-volume, highly complex diesel injector. When Continental received $100 million of new capital to support a new product launch, they knew they needed a solution to remove the old diesel injector from their lineup so they could concentrate on their new programs.

SOLUTION: We crafted a contract that would allow PurePower to buy all existing capital, take over the supply base for costed bill of materials and PPAP the product within our facility in Blythewood. Our program managers oversaw the whole process, complete with a production buildup of three months to accommodate the time for transfer and to requalify the equipment.

RESULT: Flawless execution. We completed the buildup with zero quality defects, completed transfer and requalification of equipment faster than estimated, and completed PPAP on time with the customer — all with zero defects from launch to present.

case study #2

navistar

PROBLEM: Navistar had an overseas supplier that was shipping poor-quality components that were causing engine line downtime. The supplier was not capable of machining for very close tolerance dimensions — under 10 microns — with complex GD&T reference to multiple datums.

SOLUTION: Within eight weeks, we created a fixture, programmed a Mazak 630 VMC, qualified the fixture, completed level 3 PPAP, and shipped the product in custom returnable dunnage. The part has been defect-free for over three years.

RESULT: Our customer’s issue was resolved with zero line downtime for this component.

case study #3

Fuel System Tech Startup

PROBLEM: Many startup companies have invested heavily in advanced development capabilities and IP. What most of them lack is the infrastructure to design a product that can be manufactured, make prototypes, and test these prototypes.

In this particular case, the company had OEMs willing to test its product if it was able to show that:

- Il prodotto può essere fabbricato in grandi volumi a un costo ragionevole, e

- I risultati dei test sulle prestazioni del prodotto hanno mostrato miglioramenti rispetto alle tecnologie prevalenti.

SOLUTION: Poiché PurePower progetta e collauda componenti di sistemi di alimentazione da oltre 15 anni in un contesto di grandi volumi, siamo stati in grado di fornire un'ampia assistenza, riprogettando il prodotto insieme al cliente. Abbiamo fornito un progetto e un preventivo di produzione per dimostrare la fattibilità del prodotto per la produzione in grandi volumi. I test condotti sui nostri banchi di prova hanno dimostrato che il prodotto era superiore alla tecnologia attuale.

RESULT: Il cliente è stato quindi in grado di completare la fase successiva, che consisteva nel far testare il prodotto a diversi OEM.