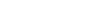

PurePower is Your Trusted Partner

Our experience as an OEM insider allows us to develop products that stay ahead of market and regulatory trends, delivering uncompromising quality, durability and fuel economy.

Our vertically-integrated process allows us to bring quality products to market faster and more efficiently.

design

- In-house design department

- Long-time industry experience

- Design processes with manufacturing in mind (DFM)

development

- Dedicated project management office

- Development processes based on industry-leading OEM

prototype

- In-house prototype department for all high-precision processes

- Experienced in complex assemblies like fuel injectors and valve

INDUSTRIALIZATION

- Launched multiple complex products on-site

- Strong interaction with development process

validation

- Fully equipped test lab for performance and durability testing

- Engine test facility to test products on complete engine

- Hot Gas stand to simulate engine-out air flow to test turbo chargers, EGR valves, EGR coolers and other exhaust components

ppap

- Use of OEM industry-standard launch process

sop

- On-time Start of Production with use of dedicated project managers

FLAWLESS LAUNCH

- Use of gate process to ensure highest quality launch

- Management involvement in gate reviews assures adequate resource allocation

WARRANTY

- Single-digit PPM warranty for most of our products

- In-house warranty center for analysis and quick feedback

CONTINUOUS IMPROVEMENT

- Continuous improvement program including all employees

- Continuous improvement projects are handled via project management to ensure quality

REMANUFACTURING

- Remanufacturing experience since 2006

- Use of OEM-quality manufacturing and assembly processes

- Assure OEM-like quality on all our parts

REVERSE ENGINEERING

- Use of OEM new product engineering processes

- Use of test and validation processes and tools like OEM/new parts

- World-class metrology lab for all dimensional verification